HNC Electric PLC-i

HCS

- HCS Series - Economic PLC MPU

- DI: 4 - 8

- DO: 4 - 8 (relay, transistor NPN or PNP)

- AI: 0 - 2

- AO: 0 - 2

- TCP+485

- Expansion modules: 3

HCG

- HCS Series - Standard PLC MPU

- DI: 4 - 8

- DO: 4 - 8 (relay, transistor NPN or PNP)

- AI: 0 - 2

- AO: 0 - 2

- Pulse input: 1 or 2 Channels A/B phase 2 or 4 points 200K

- Pulse output: 1 or 2 Channels A/B phase 2 or 4 points 200K

- TCP+485

- Expansion modules: 15

HCM

- HCS Series - High Performance PLC MPU

- DI: 8

- DO: 8 (relay, transistor NPN or PNP)

- Pulse input: 4 Channels A/B phase 8 points 200K

- Pulse output: 4 Channels A/B phase 8 points 200K

- TCP+485

- Expansion modules: 15

Hardware features:

- 1. Easy selection: Product model naming is easy to understand and convenient for model selection.

- 2. Structure optimization: Optimized structure design, compact size, beautiful appearance, saving installation space.

- 3. Easy wiring: Direct insert terminal, humanized design, more convenient wiring.

- 4. Integrated analog interface: The PLC main unit integrates DI/DO and AI/AO with flexible configuration and higher cost performance.

- 5. Ethernet + : Ethernet and RS485 interfaces are standard on the PLC main unit, supporting simultaneous operation of two communication ports. Each communication port can be programmed and networked as a master or slave station.

- 6.1+15+256: A single main unit can expand up to 15 modules, with a maximum expansion capacity of 256 points.

- 7. Unlimited networking: PLC main unit can be networking, theoretically can form unlimited points control network, a perfect substitute for medium or even large PLC system.

- 8. High-speed pulse interface: PLC main unit supports up to 4 channels A/B phase (8 points) 200KHz high-speed pulse input/output.

- 9. Perfect temperature control: Thermal resistance, thermocouple and unique temperature& humidity sensor modules, etc., perfectly meet the application requirements of process control.

- 10. Communication + : Communication extension module with isolation to meet stable communication extension requirements.

Programming software features

- 1. Three programming languages: HPMaster is a PLC programming software conforming to IEC 61131-3, which supports LD (ladder diagram), FBD (function block diagram) and IL (instruction table).

- 2. Good compatibility: Stable operation in Win98, Win200X, WinXP, Win7, Win8, Win10 and other operating systems.

- 3. Prompt message and help function: All instructions and detailed information of hardware modules can be opened in the software through F1 key to find the answer. Even if HPMaster programming software is used for the first time, the program can be easily written.

- 4. Three-level password protection: Password for project files, password for PLC, password for individual program blocks, and protection functions such as preventing program upload.

- 5. Modular program project structure: Up to 63 program blocks can be established (including main program, subroutine, interrupt program), programming language can be chosen arbitrarily, execution order of program blocks can be adjusted arbitrarily, each block can be imported and exported separately and has the same password protection as program project.

- 6. Cloud programming: The built-in cloud engine enables PLC remote programming, download, firmware upgrade, diagnosis, monitoring and debugging through HNC cloud, enabling easy remote connection and detecting on-site conditions at any time. Locally, the PLC can be programmed with a cloud engine built into the TP300 series HMI.

- 7. Program simulator: Can be simulated running PLC program in the case of complete separation from PLC,greatly reducing field debugging time and improving debugging efficiency.

- 8. Communication simulator: Equipped with a communication simulation tool specially designed for debugging communication instructions, it can simulate the process of PLC executing communication instructions and processing the data returned from the slave computer.

- 9. Interpolation simulator: Track and draw the motion trajectory generated by motion control instructions such as linear interpolation and circular interpolation, display the current position, mechanical origin position, output mode, etc., of the channel, or set the axis length and unit pulse number.

- 10. Online monitoring and debugging function: Provide up to 10 pages of component monitoring table, can choose to display data in different data formats, support mixed monitoring of bit components and register components and display component notes at the same time.

- 11 Unique real-time curve function: Real-time curve monitoring can be carried out on any register components to facilitate process control and debugging.

- 12. PLC execution file: The PLC source program can be generated into a PLC execution file that can be independently released and executed, convenient and safe to give the PLC execution file to the end user to download, there is no need to worry about the user knowing the source program content.

- 13. Firmware upgrade function: No matter CPU host or extension module, firmware can be upgraded for free. Even the previously purchased products can have various latest functions continuously introduced.

- 14. Powerful online PLC function: It can search out all PLC connected with the PC, show the information and status of all online PLC, and can choose any PLC for online monitoring, program download, firmware upgrade, control PLC running stop, etc.

Programming instructions features

- 1. Powerful innovation convenience instructions: on the basis of analyzing and absorbing various EXISTING PLC instructions, many powerful innovation convenience instructions are launched. Such as communication instruction (MODR, MODW HWRD HWWR), PID control (PID), valve control (VC), upper and lower alarm (HAL, LAL), send (SC), the temperature curve radius (TTC), only one instruction can implement other brand PLC need multiple instructions to realize the function, greatly improve the efficiency of programming and program run faster.

- 2. Instruction routines: In the help document, all instructions are explained in detail and corresponding routines are supported to be opened and downloaded into PLC.

- 3. Rich communication protocols: built-in Modbus TCP, Modbus RTU/ASCII protocol, free communication protocol and HNCbus high-speed communication protocol instructions independently developed by HNC.

- 4. Powerful communication instruction: No matter use what kind of communication protocol is simply a communication instruction can complete complex communication function, no conflict, to send and receive control for communication port, communication interrupt handling problems such as trouble, and the same communication port can use different protocols, complete the required all sorts of data exchange easily.

- 5. Powerful analog input processing: AI register can be used to directly access analog input, analog input support engineering conversion, sampling times setting and zero correction.

- 6. Powerful analog output processing: The analog output can be directly controlled by AQ register. The analog output can support engineering conversion and can be configured with blackout output holding function.

- 7. PID control function: Support 32 incremental PID, 32 self-tuning PID, 32 fuzzy temperature control, with TTC temperature curve control, VC valve control and other instructions to easily achieve a variety of complex control requirements of industrial site.

- 8. High-speed pulse instruction: Supports acceleration and deceleration pulse output. The unique synchronous pulse output instruction can easily realize accurate synchronization control. The single machine supports 8-channel pulse width modulation output (PWM) and can drive 8 servo or stepper motors at the same time.

- 9. Motion control function: The single machine supports 8-axis 200KHz motion control, linear interpolation and circular interpolation of any 2-axis, absolute position, relative position, reverse clearance compensation, origin regression, electric origin definition and other functions.

HNC Electric HMI i H-BOX

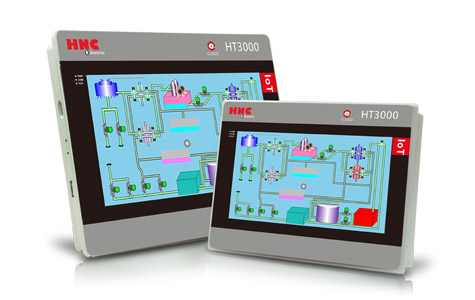

HMI HT3000 IoT

- Display: 7˝ ili 10˝ TFT

- Rezolucija: 800x480 ili 1024x600

- Flash: 4GB

- RAM: 512 MB

- Micro SD

- SIM card, 4G network

- COM port: RS485 / RS232

- 2 x USB 2.0

- Wi-FI: 802.11b/g/n

- IP 65 (-10° do +60°C)

- Napajanje: 24 VDC

HMI

- 1. 16 million true color TFT LCD, LED backlight, rich and real content. 4G Flash + 512M RAM.

- 2. Integrated HNC Cloud service, built-in HNC cloud engine. Support serial port / U disk / SD card / Ethernet / HNC cloud and other methods of program download.

- 3. Support third-party SCADA software programming management. Support cloud/mobile phone access control, strong operability.

- 4. Innovative A/B Key security mechanism, multilingual automatic translation, mobile payment support, weather forecast display.

- 5. Multi-screen networking. The innovative network networking method is easy, fast, convenient and practical. Support multiple terminal size screen custom display, multi-screen interactive management.

- 6. Support MQTT protocol. Can be connected to the database server, easily realize data collection and reporting, and dock with ERP/MES and other systems.

- 7. Support cloud transparent transmission. Can remotely program, upload and download, firmware upgrade, diagnosis, monitoring and debugging PLC program. Detect on-site abnormal conditions anytime and anywhere.

- 8. Support edge computing. Realize edge computing through the built-in script engine, function calculation, and interaction with device data in the terminal.

- 9. Support multiple third-party protocols. Built-in a variety of industrial equipment drivers, support the current mainstream PLC,VFD, instruments.

- 10. Integrated cloud access & alarm push, You can easily perform remote cloud access control on local or remote HMI devices through cloud APP and cloud website. Real-time abnormal monitoring alarm, the alarm information is pushed to the designated management personnel in real-time. Alarm notifications can be received via mobile APP, SMS, etc.

H-BOX-E

- Flash: 4 GB

- RAM: 512 MB

- SD card slot

- SIM card, 4G network

- COM port: 2 x RS485 / RS232

- 2 x USB 2.0

- 2 x LAN

- Wi-FI: 802.11b/g/n

- WLAN: 4G/3G/2G

- 0° do +55°C

- Napajanje: 24 VDC

H-BOX

- 1. 4G Flash+512M RAM. Small size, multi-function, high cost performance

- 2. Integrated HMI function, you can directly monitor the display screen through the mobile phone terminal/PC terminal insteadof t he HMI screen, the control is flexible and convenient

- 3. Innovative A/B Key security mechanism, multi-unit network, database, multi-screen interaction, cloud camera remote monitoring and other functions

- 4. Support MQTT protocol. Support access to database server, easily realize data collection and reporting, and dock with ERP/MES and other systems

- 5. Rail mounting. With two Ethernet interfaces, supporting star, tree, and bus Ethernet networking

- 6. Supports third-party SCADA. Built-in HNC cloud engine, integrated HNC cloud service, support cloud/mobile phone access control support edge computing. Realize edge computing through the built-in script engine, function calculation, and interaction with device data in the terminal

- 7. Support cloud transparent transmission. Can remotely program, upload and download, firmware upgrade, diagnosis

- 8. Monitoring and debugging PLC program. Supports various third-party protocols to detect abnormal conditions at any time

- 9. Built-in a variety of industrial equipment drivers, support the current mainstream PLC, inverter, instrument