eepos

eepos one

- Load capacity of up to 2,000 kg.

- 7 profile sizes

- low dead weight with high rigidity due to hollow chambers

- external and internal item grooves

- reinforcement profile for reinforcing loads

- one eepos trolley is suitable for all profile sizes from XS to XXL

- extensive accessory options

- ergonomic and fatigue-free working due to an excellent, jam-free smooth running design

- low noise emission reduces the workload

- High-quality and low-wear components guarantee maximum value retention and cost-effectiveness over the entire operational lifetime

- fast design, delivery and assembly

- reduced lead times due to high working speed and positioning accuracy

- simple assembly due to intelligent modular design

- built-in service stations allow easy replacement of trolleys

- eepos one profiles are made of the aluminium alloy EN AW 6063 T66, so that the eepos one area crane systems work safely and reliably in production halls, on production lines, assembly lines, work stations and also in harsh environments.

Advantages:

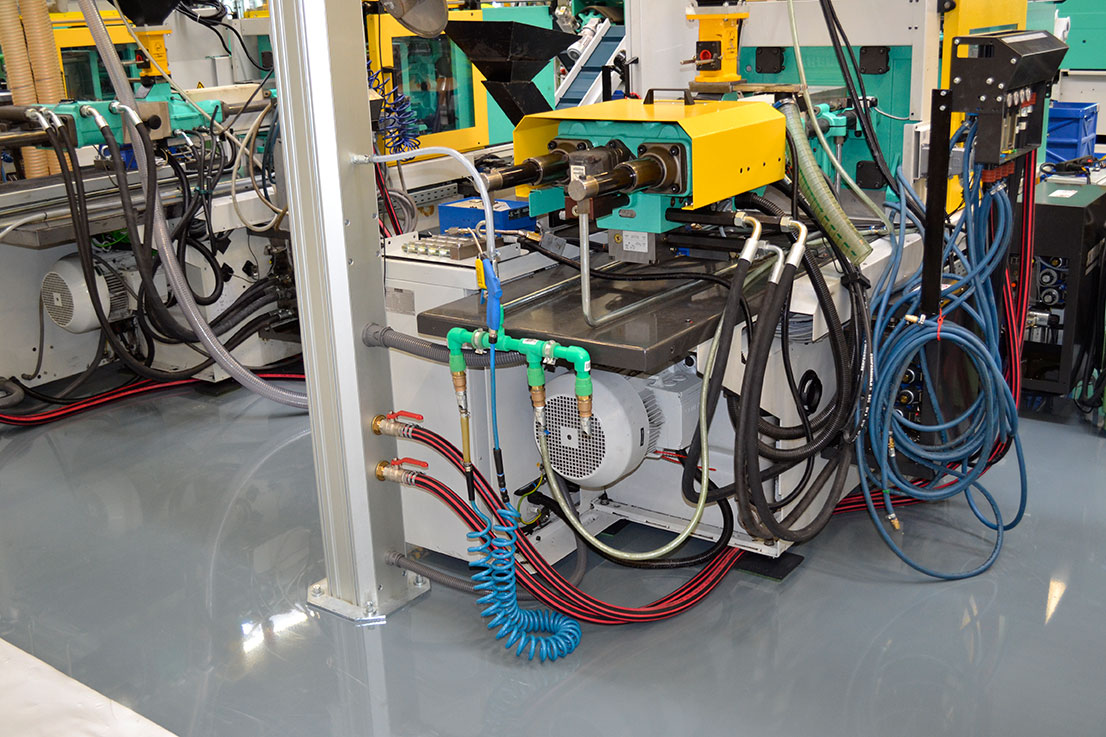

eepos base

- Up to 3,000 mm in length as standard, while longer lengths are available upon request

- 4 sizes available (XS, S, M, L)

- Media supply from below, above, and from the side are possible

- Optional jib crane is possible from media column profile M. One-sided or two-sided construction up to 100 kg load capacity and 3,000 mm boom length. Swivel cantilevered jib cranes made of carbon fiber are standard, aluminium on upon request

- 12 different module inserts that can be freely interchanged with each other.

- All module inserts are easy to assemble and disassemble

- Easy implementation of additional module inserts

- Item-compatible grooves outside and inside the column allow the user to add his own attachments (e.g. for strain relief of cables and hoses)

- Spacious interior design for cable and hose installation

- Supply of any desired workplace with media (electricity, compressed air, water) and information (network). Technical gases on request.

- Easily configurable

- Optional jib cranes on the media column up to 100 kg payload possible.

- Four item compatible grooves on both the inside and outside of the column allow for one’s own attachments.

Advantages:

eepos powertrack

- Load capacity per busbar 100 A, from basic box 20 A

- 230/400/690 Volt version possible

- Maximum length: unlimited if the installation regulations of the busbars are observed

- Feed-in by means of head and/or line feed-in

- Modular design with plug-in modules and connectors for safe and uncomplicated power supply

- New installation and retrofitting of systems flexible and easy to implement

- The busbar supports can be attached to the outside of the eepos profile and up to 9 conductor rails can be attached without tools

- Simple mounting of the receiver box frame on the steel construction or on eepos profiles with diamond stones

- Completely wired internal part of the receiver box is only inserted

- Double current collectors reduce contact resistances at the individual phases

eepos move

- The eepos move lifting axis was developed for tool handling, container and load transport up to 500 kg, and 2,500 Nm torque absorption of off-center forces

- Installation dimension and stroke of the lifting axis are determined specifically for each customer

- eepos move S and L can be supplied as individual lifting axes or can be completely assembled including lifting motor or pneumatic control system

- optional with trolley frame and swivel bearing

- easy and ergonomic handling of eccentric loads

- heavy-duty, smooth-running and backlash-free, and low-maintenance even with off-centered loads

- eepos move also offers various mounting options through external item grooves

- modular design with compact external dimensions (eepos move S: 130×130 mm for outer telescope segment T13, eepos move L: 250×250 mm for outer telescope segment T25)

- hollow chamber design allows optimum balance between weight, stiffness, and stability

- fast pre-assembly and assembly possible thanks to standardized components such as extruded profiles, bearing units, etc.

- version with spring balancer, electric chain hoist or pneumatic control are available according to customer specifications

- depending on the application, the eepos move lifting axis must be equipped with a torque cross and/or torque support or trolley frame, especially for screw applications or similar cases where torsional moments may occur.

eepos nano

- highest load capacity with minimal overall height

- low weight

- unique ergonomics to retain manpower and short work cycles

- modular, changeable structure with flexible connection of various components

- the groove system is compatible with the "item construction profiles 5"

- available in 3 profile sizes: nano 40, nano 60 and nano 80

- Loads from 15 to 75 kg, depending on profile size

- four external item grooves for suspending the profiles and fixing individual components

- curved profiles are also available in individual radii from 750 mm

- can be combined with the jam-free and low-noise eepos trolley

- can be used as a slewing jib crane up to four meters with a 40 kg load